We specialize in private label

Manufacturing of

Perfumes

Our team creates custom perfumes, bottles them, and packages them with exceptional support and service.

About Us

Al Rawad Perfume Industry is a leading manufacturer and marketer of global perfumes. In 2020, Al Rawad Perfumes launched its state-of-the-art manufacturing unit based in the new industrial area, Mussafah – Abu Dhabi – MW4 – United Arab Emirates. Today, we have the capacity of 10,000 Unit Production per Day which is managed by our highly professional and experienced production team.

We are passionate about our work and believe in giving our customers superior quality and superior services. That’s why we have an amazing team committed to bringing every scent you want in your perfume line to life. We have worked with a large client base ranging from some of the most prominent perfume houses in the UAE and GCC, celebrities, famous fashion brands, and entrepreneurs and we are ready to work with you to launch your perfume line.

OUR VISION

Brings together a team that will collectively

develop models that allow us to provide better

solutions effectively and efficiently in

the highest quality standards.

OUR SERVICES

Custom Mould Projects

Each perfumer is dedicated to translating emotions into scents. Inspired by different cultures they use only the finest quality ingredients to create sophisticated and diverse fragrances. Projects are driven by our account managers, acting as the voice of the customer and ensuring that their expectations are met and surpassed. Quality, regulatory and safety experts ensure top levels of compliance.

Bottle Coating

The coating is a decorative solution that allows coating an entire packaging or a part of it. only uses UV paints that are sprayed on the surface to be printed.

The coating can be applied to glass, plastic, wood, and metal and can be: soft, transparent, opaque, glossy, matte, glittery, iridescent or created in many other ways. In other words, UV coating is the ideal solution when you want to completely transform the appearance of the packaging, for example, to make a clear glass bottle become white.

For these characteristics, the coating is a process that is always combined with one or more printing techniques such as screen printing and pad printing.

Screen Printing

We offer a range of ink colors, including black, white, and metallics (gold and silver), as well as custom color matching via the Pantone Matching System (spot coloring).

The standard colors for no additional cost are black and white.

A note on Pantone colors: We do the best we can to match to the Pantone Coated Spot Color guides. While it’s an excellent system for specifying color, it’s not a perfect system, as sometimes there can be slight variation — even within the Pantone system from swatch book to swatch book.

Please also keep in mind that viewing colors on a screen is not recommended, as they are backlit RGB. Colors printed on glass are reflective, which is a totally different “color space.” Viewing colors in the coated Pantone spot swatch book is the only recommended way. While we do not have all the Pantone colors as pull-out chips, we have many available.

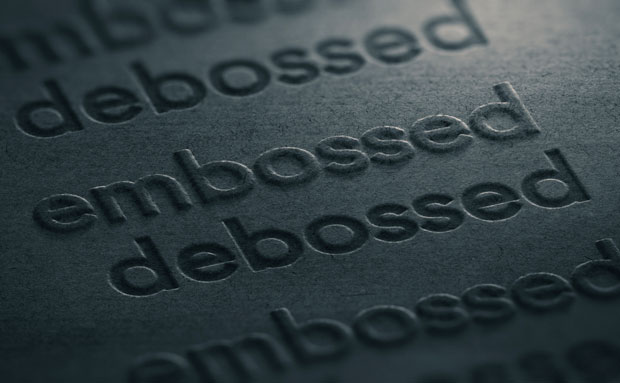

Emboss & Debossing

Actually the two are similar in processes, the difference being that with embossing the image that is embossed is raised up and with debossing the image is indented into the paper. Dies or plates are necessary to produce these effects. Above is a picture of a snowflake die along with what is called the counter. The die in this picture is the copper piece which shows the snowflake image etched into the copper. The counter is the whitish looking piece with the black snowflake on it. When embossing, the two mating pieces are positioned in the press so that they line up perfectly with one another. As the press closes the paper is pressed into the copper die by the counter. It’s a very similar process to how a notary or corporate seal works when pressed into the paper.

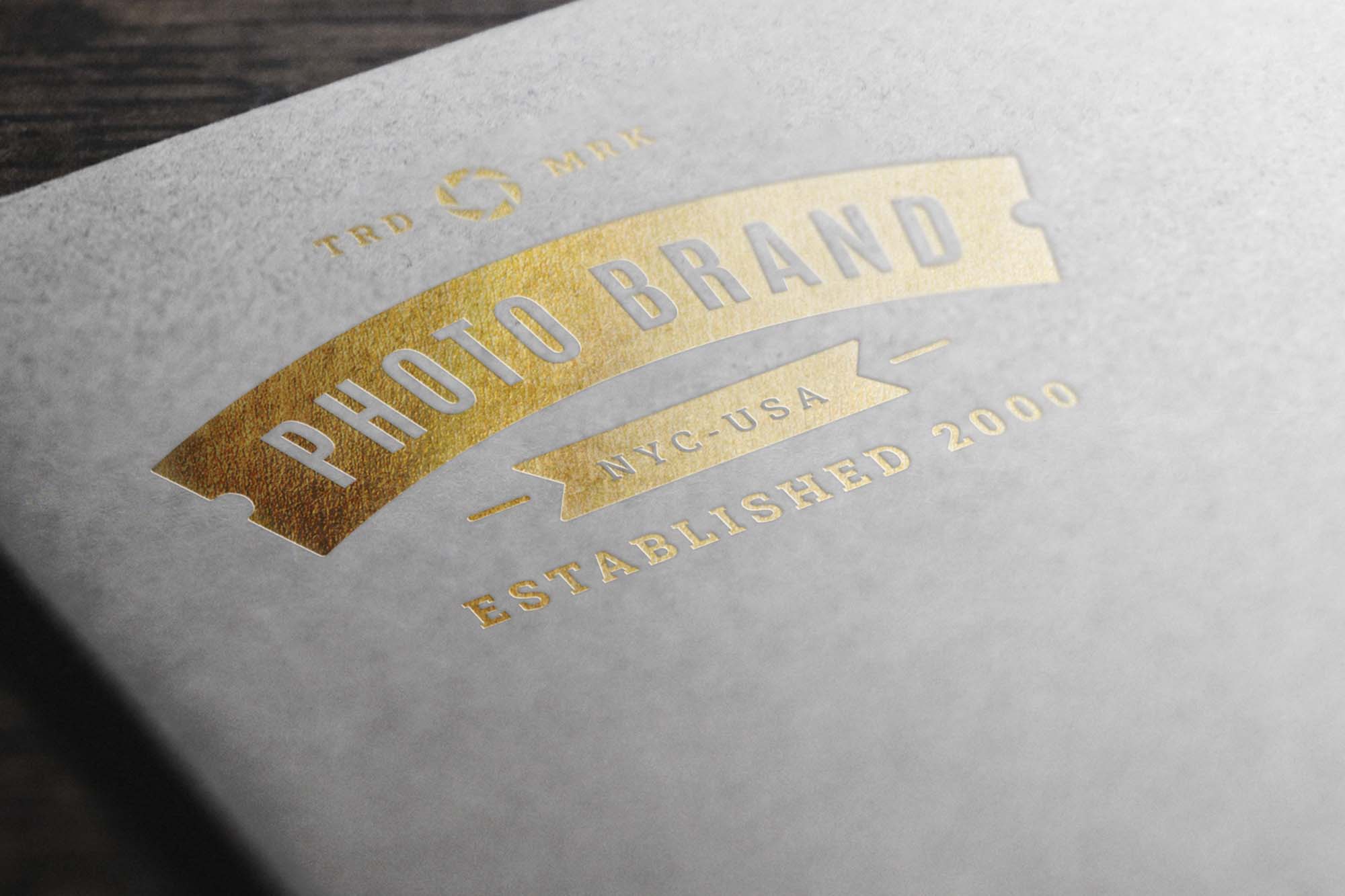

Foil Stamping

Foil stamping is a process in which a thin layer of foil is stamped onto paper by a heated raised metal die. There are many colors and finishes of foil to choose from.

Our Process

Vibrant top notes, lush middle notes & powerful base notes, all blended into a symphony of aroma - breathe in and let the fragrance work its magic in your mind.

Tailored service with exceptional quality.

LET US DESIGN AND DEVELOP YOUR PERFUME ACCORDING TO YOUR SPECIFICATIONS

The fragrance is then left to soak (cure) for at least 30 days

Bottle, Labels, Stickers, and Cap Selection

Artists design & create packaging to your vision

Get in touch

M32 -Mussafah,

Mussafah 32/1

Abu Dhabi, U.A.E

MON-SAT 09:00 -06:00

SUN – OFF